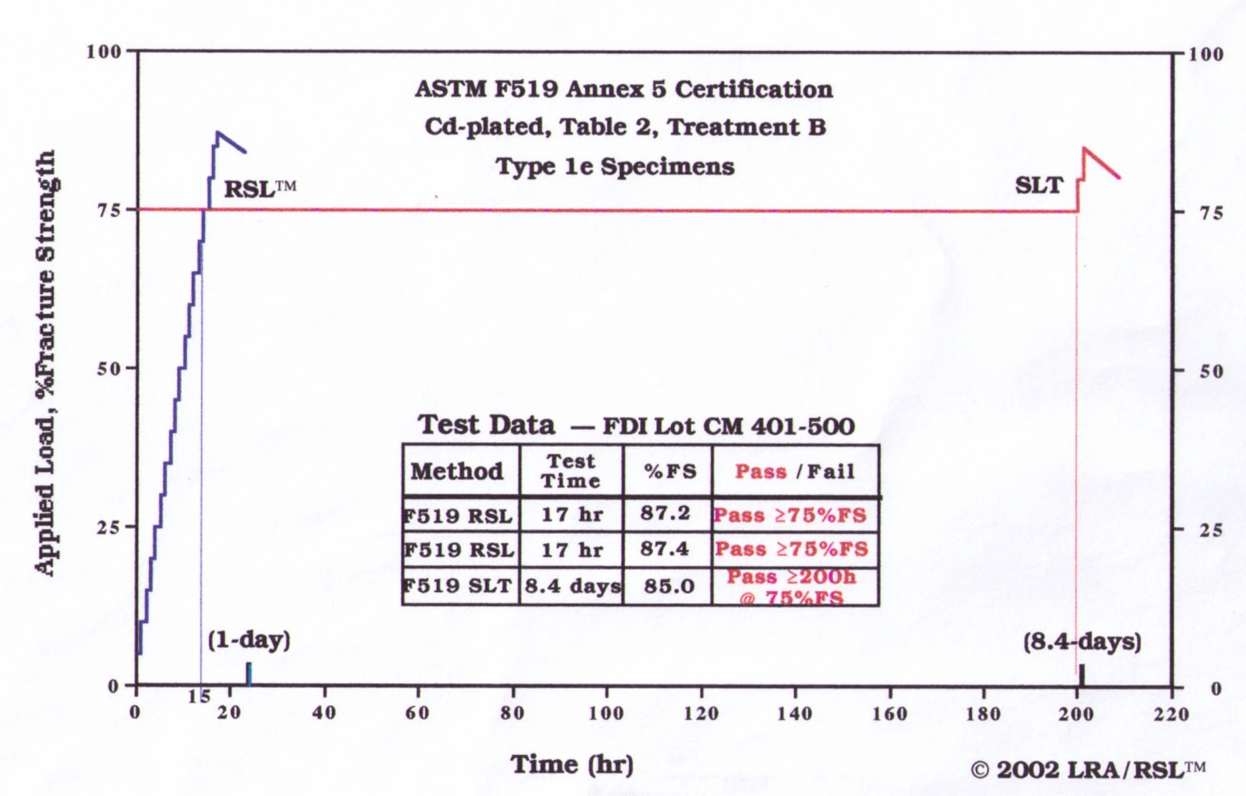

We use the Rising Step Load (RSL) method to understand fracture mechanics and cracking at the speed of production.

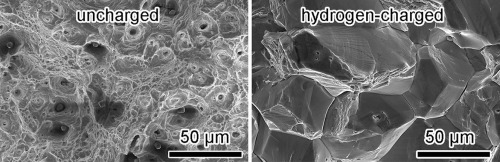

By incrementally increasing the load over time and using a sensitive load cell, we can find the fracture mechanics values for materials in a small fraction of the time required for most other tests. This is extremely helpful for comparing candidate materials or coatings that may be susceptible to hydrogen embrittlement, stress corrosion, and other environmental cracking mechanisms.

Just as importantly, the RSL evaluation provides a quantitative measure - an exact value of the threshold - rather than just a pass/fail test at a selected threshold. So you get more actionable data and can monitor the performance of your materials over time.

Extensive tests have demonstrated the equivalence with long-term test methods.

Save money and time by rapidly testing every batch of material without having to wait months!

We can pinpoint the threshold to within 1-2 % of the maximum sustained load.

RSL can help you pick the optimal materials for your application and determine the maximum safe loads far more accurately than other sustained load testing can. So you can design and build the best possible version of what you want to make.

It started with aerospace - but now it's spreading across the world to every industry. We are passionate about bringing the Rising Step Load process to help make the world a safer place by preventing environmental corrosion through science and data.

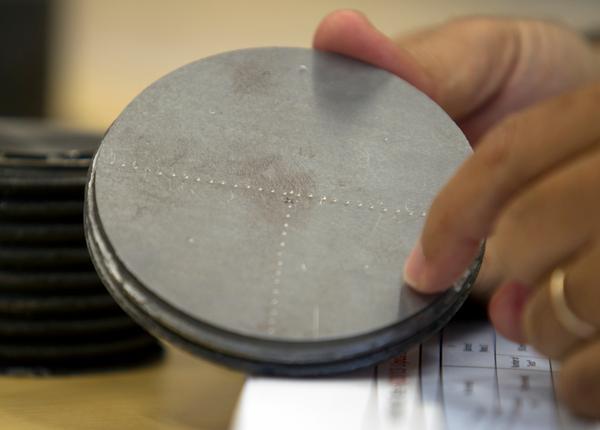

High-strength metals are the building blocks of our society. Our technology allows you to ensure they are safe and will be long-lasting.